I’m excited to announce the release of Printing Presses. This sound effects library showcases a variety of high-powered and dynamic mechanical sounds from three massive web-offset newspaper presses operating at high speed. In addition, you’ll hear unique mechanical sounds found inside a newspaper’s plate room and packaging department before and after a press run. Plus, I recorded three letterpresses. Each sound is captured with multiple microphone setups at various locations providing detailed and overall perspectives. Listen to presses increasing in speed, humming along at running speed and then coming to a stop. Sometimes gradually, sometimes suddenly. I’ve also created condensed versions of entire press runs as they can be long, presenting them as ‘sequences.’ In addition, some sounds have been meticulously edited and presented as seamless loops.

Recording web-offset newspaper presses

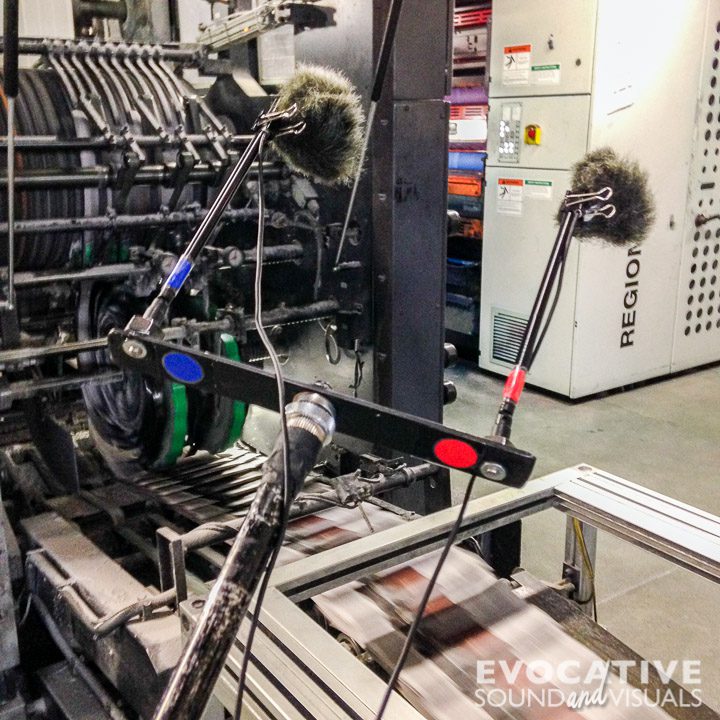

I captured two of the three web-offset newspaper presses in the same manner, by planting a Sound Devices 702 recorder with a stereo pair approximately 10 to 15 feet from the press on the first floor. This provided me with a nice overall sound. For one press I used Audio Technica 3032 Omnis in a DIY SASS setup. For the other, Line Audio CM3 cardioids in ORTF. Then, to capture details, I walked around, sometimes into the belly of the beast, with a Sony PCM D100 recorder using its onboard mics.

Let’s say a scene calls for an editor running into the pressroom shouting, “Stop the presses!” I’ve got the perfect sound for that. At one facility, I happened to be recording when a web broke, shutting down the run in a hurry. Secretly, I was hoping this would happen, as it provided me with one more sound to add to the library. But don’t tell the press operators. Time is money for them.

Newspaper presses are amazing machines to see, hear and feel. They’re loud, multi-story man-made mechanical marvels that crank out one broadsheet newspaper after another at high volume. They are anchored in enormous rooms the walls of which were most likely built around them. Wonderfully wobbly-sounding aluminum plates meet up with blazingly-fast spinning cylinders, turning ink into information. Cold-set, uncoated newsprint flows at breakneck speed on a continuous roll of paper, called a web, before being folded, cut and carried on conveyors.

These roller coaster-looking conveyers transport newspapers to the packaging department, formerly called the mailroom back in the days of rural free delivery. Sounds captured from machines in this department, like the binder, bundler, bander, stacker and inserter, in addition to sounds found in the plate room before a press run, like the plate punch and bender, are just as interesting and unique as the presses themselves.

Recording letterpresses

I recorded an electrified cast iron 1902 Chandler and Price ”craft’ letterpress operated by a small business owner in Boise, Idaho. Walking around a local museum’s basement allowed me to record a small 1940s Kelsey 5×8-inch lever-action letterpress. I called a nearby commercial printer to record a sheet-fed offset press made by Ryobi in 2015. The morning I visited their shop, the press was cranking out a slick four-color booklet for a lighting company at 8,500 sheets per hour. It picks up each piece of paper with suction cups, which create quite an intriguing sound. Much like newspaper presses, when these letterpresses are humming along at running speed, they have rhythmic voices I that can listen to for hours.

Listen to a Preview of Printing Presses

Library Specifics

- 78 files at 96kHz/24bit, 3.6 GB, 104 minutes

- Recorders used: Sound Devices 702 and Sony PCM D100

- Mics used: Line Audio CM3 (ORFT), Audio Technica 3032 (SASS), two Barcus Berry contact microphones

- UCS compliant

- Metadata applied via Soundly and BWF MetaEdit

Presses Featured in this Library

manroland Regioman

A web-offset newspaper press printing at approximately 65,000 copies per hour.

DGM (Dauphin Graphic Machines, Inc.)

A web-offset newspaper press printing on a 32-inch single wide web.

Goss Colorliner

A web-offset newspaper press printing the November 20, 2024 editions of the Wall Street Journal and Buffalo News on two separate presses inside the Cleveland Plain Dealer printing facility in Brooklyn, Ohio. The press was running at 40,000 copies per hour. Each press weighs 1,100 tons and is 100 feet long. The largest full roll (four pages wide printing front and back) of newsprint is 44 inches wide, 50 inches in diameter and weighs approximately 1984.16 pounds (900 kg).

Ryobi 754G

A four-color (CMYK) letterpress press made in 2015, printing a lighting company booklet at 8,500 sheets per hour.

Chandler and Price

An antique letterpress cast in 1902

Kelsey

A vintage cast iron 5×8 inch lever-action letterpress from the 1940s.

Why I Wanted to Record Printing Presses

I desperately wanted to record these newspaper presses before they disappeared in order to help preserve and share their impressive sounds. Here at the beginning of 2025, it’s no secret that the newspaper industry is in a state of rapid decline. I’ll take an educated guess and say that your hometown newspaper is a shell of its former self, the page count that is. Hopefully, not its content. Sadly, as we consume more of our news on phones and tablets, more newspaper presses are being shuttered and sold for scrap.

I heard my first newspaper press one going full bore some 30 years ago as a beginning newspaper photojournalist working for my hometown newspaper, the News Journal in Mansfield, Ohio. Back then; they used a Goss Metroliner double-wide press. You could hear it humming along from the newsroom. I loved it. It meant that what so many talented people produced hours earlier was about to be bundled up and sent out the loading docks to inform our readers.

My hope is that one day, long after the last newspaper press grinds to a halt and is unceremoniously hauled to the scrapyard, these sounds will evoke memories for all the people that have ever had a hand in making a newspaper the old-fashioned way.

Aaron Phipps, Director of Production at Advance Local in Cleveland, Ohio, puts the unique sound of a newspaper press into words much better than me. “A press running at the high end of its speed rating is a dream to listen to, it takes on a totally different character, the ink is flowing, the water is moving, the gears in their oil bath are doing their thing, the pipe rollers are singing, the dust collection system is purring along; this mechanical marvel almost seems alive when it is let loose. The patterns of sound take on a rhythm, kind of like breathing.”

A press running at the high end of its speed rating is a dream to listen to, it takes on a totally different character, the ink is flowing, the water is moving, the gears in their oil bath are doing their thing, the pipe rollers are singing, the dust collection system is purring along; this mechanical marvel almost seems alive when it is let loose. The patterns of sound take on a rhythm, kind of like breathing.”

Aaron Phipps, Director of Production at Advance Local

Thanks to the Following

- The Idaho Press in Nampa, Idaho allowed me to record the paper’s single-wide DGM press and the packaging department on the night of its Thanksgiving Day 2018 newspaper production run. Together with all the inserts, they produced a huge newspaper that evening.

- Angela Stewart, owner of Ladybug Press in Boise, Idaho. Back in 2019, Angela allowed me to record the vintage 1902 Chandler and Price letterpress she uses inside her one-room studio.

- The Bedford Historical Society. Archivist Jack Dragga graciously worked with me several times while I asked him to perform a sound on an antique item “just one more time.” Also with his assistance, I recorded quite a few of the sounds for my Typewriters sound effects library.

- Michael Duhr, co-owner at Foote Printing in Cleveland, Ohio. Michael kindly allowed me to record his company’s 2015 Ryobi 754G sheet-fed letterpress. With its suction cup action grabbing each sheet of paper, it produces a sound that is totally different from the newspaper presses I am used to experiencing.

- Aaron Phipps, production director at Advance Local. I lucked out when I cold-emailed the publisher of the Cleveland Plain Dealer asking to record the sound of their presses. Phipps had this very idea on his mind for some time, ever since overseeing the closure of the Grand Rapids Press printing facility he headed in Walker, Michigan. I’ve never met anyone so knowledgeable and passionate about newspaper presses. Like a seasoned auto mechanic listening for trouble under a car, Phipps will often walk around his presses picking out subtle sounds among the noise. He instructed me on where to stand in order to capture the best possible audio. He keeps an impressive archival collection of historic newspapers. Phipps didn’t buy them based on their headlines, as you might think, but rather for the technology used to print them. I was able to touch cloth newsprint with red British tax stamps dating back to before the American Revolution. Phipps was even able to guesstimate with mathematical accuracy the running speed of the manroland Regioman press I recorded 10 years ago just by listening to a recording I supplied him of its knife box operating. Examining a one-second waveform of the sound, he placed the speed at approximately 65,000 copies per hour. He tells me the Goss Colorliners he now overseas in Cleveland can produce 70,000 copies per hour straight. To date, he’s never taken them above 40,000. According to him, his press operators would be “too spooked to run old iron at top speed, afraid something will break.” “Before this press is put out to pasture I will hear it run at full speed. To me its like having a champion horse but you won’t enter it in the Kentucky derby [sic] because something bad might happen. No glory there.” I’d love to be on hand to witness it.

- To all the newspaper press operators that allowed me to walk up and down and all around their presses during production runs. I tried not to get in your way. These professionals know their machines inside and out, tending to them from makeready (the process of setting up the press) to clean up. I love how effortlessly they swoop up a newspaper from the conveyer pickup station and inspect it for proper registration and alike. It’s like a ballet of sorts. I quickly found out that press operators were the last line of defense in insuring my work looked good in the next day’s paper. It was smart to say hello. Plus, watching one of your top-of-the-fold front page images come streaming off the press in multitude is pretty damn cool. Sadly, online-only photographers will never experience this.

- Finally, Paul Virostek and Tim Nielsen, who offered sage advice regarding to how to name and edit long raw press run files into something more manageable for a SFX library.

Behind the Scenes

List of Newspaper Press Closures

I’m grateful to have been able record to inside the newspaper facilities above. At the same time, I fear for their long-term survival. Some papers have such low circulation now they choose to print on presses hundreds of miles away. It is more economical to shutter their own and truck papers back to their circulation area. Consequently, this brings about early deadlines. Late-breaking news often goes unreported in print form and dissatisfied customers cancel subscriptions.

Community newspapers are vital to a healthy democracy. Without them, information shrivels inside news deserts and citizens get left in the dark. If you’re a traditional newspaper junkie like myself, one that prefers to hold a newspaper in your hand rather than read it online, you’ll find the following list quite depressing.

Below, I’ve collected links to articles announcing final press runs for tragically more than a few U.S. newspapers. I’ll lead off with one stark example. The Kansas City Star’s iconic 400,000 square-foot glass and copper press building, only 18 years old, is being turned into a data center. It’s four presses, silenced. The Star is currently printed in Des Moines, Iowa. Here is list of others, in no particular order:

- The Ribon Commonwealth Press of Ripon, Wisconsin

- The Moab Times-Independent in Southeast Utah

- Seacoast Media Group in New Hampshire

- The Savannah Morning News in Savannah, Georgia

- The Daily News Record in Harrisonburg, Virginia

- The Daily Sentinel in Grand Junction, Colorado

- The Spokesman-Review in Spokane, Washington

- The Herald-Tribune in Sarasota, Florida